Intelligent manufacturing solutions

Relying on the intelligent rolling equipment developed by the company and the common technology of Industry 4.0 intelligent manufacturing

Including digital twins, closed-loop control, and flexible equipment development

Empowering upstream and downstream enterprises in the rolling industry with ideas such as parallel mechanism design

Provide digital solutions

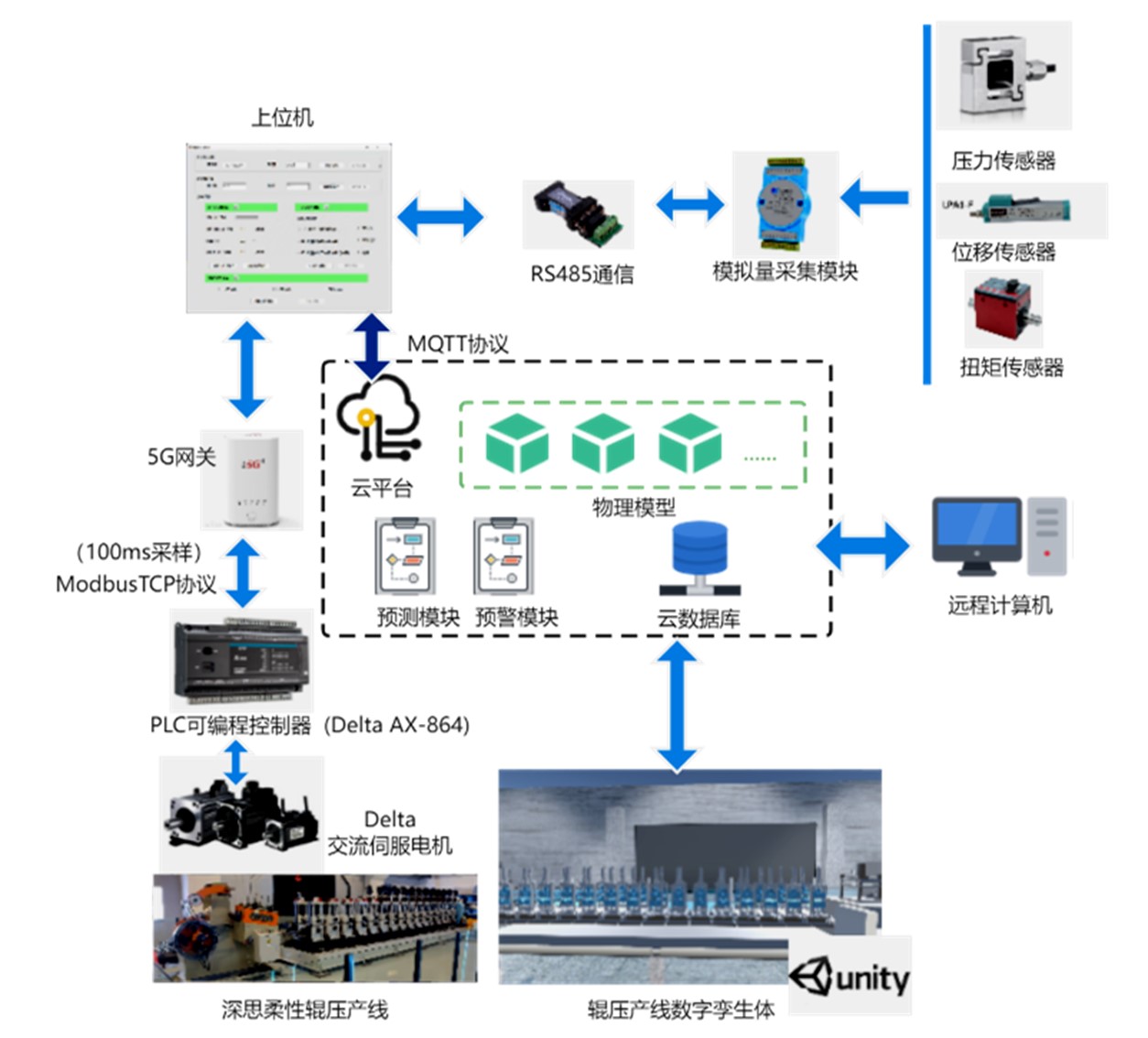

Digital Twin: Used for the interaction between digital twin models and rolling equipment, including rolling equipment and server side. The rolling equipment is equipped with servo motors and control systems, and a digital twin model is installed in the server to achieve real-time interaction between the digital twin model and the rolling equipment. The virtual rolling equipment simulated by the digital twin model is synchronized with the real rolling equipment, and the rolling equipment parameters can be viewed and adjusted at any time according to the situation, achieving the goal of efficient manufacturing.

Intelligent Decision System: The company has successively broken through key technologies such as flexible production, production data visualization, remote monitoring, AI intelligent decision-making, product accuracy self inspection, multi axis linkage precise control and process analysis, as well as online adaptive correction. These technologies have effectively improved material yield, production line efficiency, and product quality stability, and broken the bottleneck problems of traditional manufacturing that highly rely on engineer experience.

|