R&D strength

All core members of the company come from the intelligent manufacturing team of Deep Thinking Laboratory

The Deep Thinking Laboratory is affiliated with the Higher Research Institute of the University of Electronic Science and Technology (Shenzhen), and focuses on the research and development of advanced manufacturing and intelligent manufacturing systems such as industrial internet, integrated deep perception, and ubiquitous interconnection, as well as the transformation of technology and achievements in high-end equipment. The research content of the laboratory covers sensing technology, acoustic and optoelectronic technology, 5G communication technology, hydrogen energy and fuel cell technology, digital precision forming technology (such as roll forming, roll punching composite forming, etc.), additive manufacturing (such as 3D printing, etc.), digital twins, metamaterials, industrial big data, network security technology, etc. The Deep Thinking Laboratory has a high-tech intelligent manufacturing research and development team that integrates production, learning, research, and innovation. It has nearly 30 professors and researchers, as well as more than 30 doctoral and 270 graduate students.

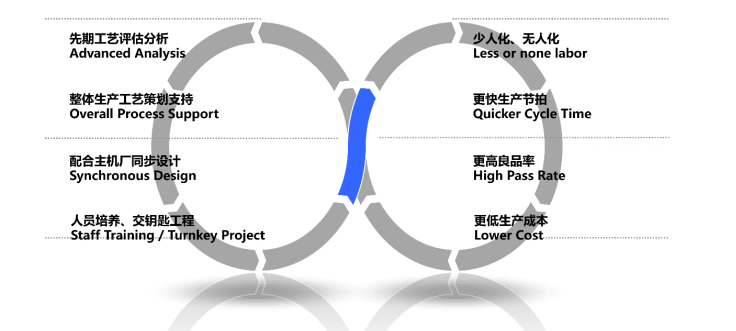

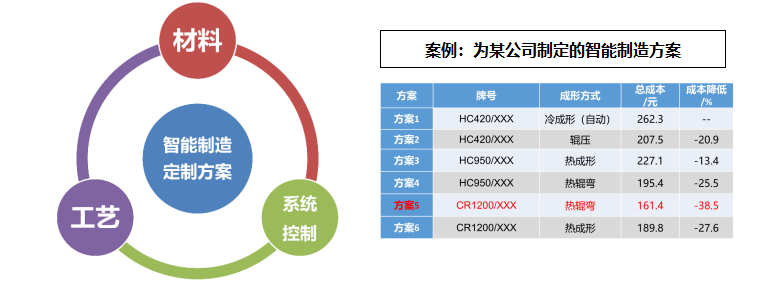

The company and Deep Thinking Laboratory have reached a deep cooperative relationship and established a joint laboratory to further promote the level of intelligent manufacturing and flexible intelligent rolling in China. Based on the actual needs of customers, we can provide customized intelligent rolling solutions from three aspects: material, process, and system control. At present, the company has reached strategic partnerships with companies such as Ningbo Chuangjie, Zhonglai, Haost, and BYD, respectively, in the fields of intelligent rolling equipment, photovoltaic products, thermal rolling, and battery manufacturing.

合作伙伴

core technology

·The first visual online detection system applied in the rolling industry in China

·The first industrial big data analysis architecture and model applied in the rolling industry in China

·The first digital twin system applied in the rolling industry in China

Business advantages

·Integrating industrial big data to create an intelligent decision-making expert system

·Collaborative Control of Cluster Equipment and Self Decision of Forming Trajectory Optimization

·Build an intelligent manufacturing equipment production and research and development system, including digital twin virtual prototype, perception interconnection technology, human-machine interaction, online image recognition technology, etc

·Focusing on the development of a large database for flexible roll forming products, including ultra high strength, lightweight, constant cross-section, and variable cross-section parts, and expanding the product database to include aluminum alloy, magnesium alloy, and carbon fiber composite materials