Image recognition technology has been widely used in the manufacturing field and has made great progress. The current traditional image recognition and detection methods have the problems of complex manipulation, slow speed and long cycle. Under the requirements of modern intelligent manufacturing including rolling forming, the corresponding online image detection and recognition and real-time feedback technology still have considerable technical difficulties. This is mainly due to the high speed of the workpiece in the rapid continuous manufacturing process, taking roll forming as an example, the speed is greater than 3m/s, which brings great difficulties to image capture and recognition, and feedback information to real-time feedback to the production line execution system under rapid conditions is also facing great challenges.

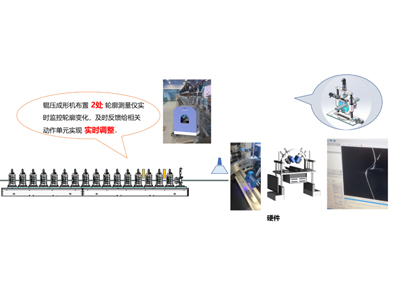

Shensi Shape has achieved a technological breakthrough in the online recognition and detection algorithm of the 3D contour of the workpiece on the intelligent manufacturing demonstration line. The intelligent measurement node of the production line can quickly construct the cross-section profile of the workpiece, accurately measure the size of the workpiece, and make the algorithm lightweight and portable, which can meet the high-speed processing speed of each intelligent measurement node under the conditions of 5G communication. It provides a new inspection method for rapid continuous manufacturing mode including roll forming, which has the advantages of large range, non-contact, intuitive, fast and high precision.