Traditional manufacturing industries/factories are in urgent need of corresponding production line upgrades. The core of promoting the upgrade of traditional factories to smart factories is to realize the comprehensive application of industrial big data in traditional factories. In the process of combining the concept of big data with the traditional factory/manufacturing industry, overcoming the problem of "stuck neck" such as key technologies of industrial big data is the key to realizing the concept of big data. Among them, the key point of industrial big data technology is to promote the comprehensive collection of core industrial data, accelerate the interconnection of industrial equipment, promote the high-quality collection of industrial data, and establish industrial big data storage platforms, warehouses, and markets with industry standards. Among them, information channel and collection are the basis of the whole process, building big data network analysis system (intelligent sensor, cloud system, etc.), human-computer interaction automation system (industrial software, online detection, etc.) is the method, and building industrial robots (manipulators, automatic guided vehicles, etc.) is an important means. The team will provide key industrial big data technology applications for smart factories in different fields for specific manufacturing scenarios, especially in the field of metal forming.

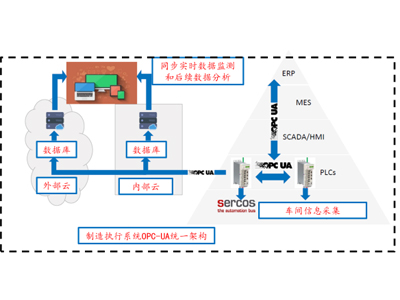

The first industrial big data analysis architecture and model applied in the rolling industry in China to build the unified virtual architecture of the cloud platform:

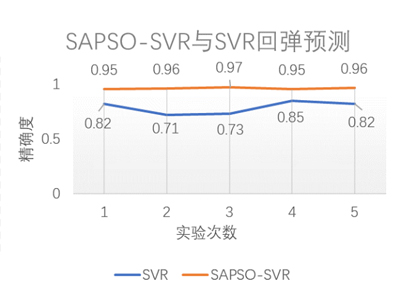

1. Establish rebound prediction model and decision model

2. Significantly improve product accuracy, reduce product production costs and development cycle

3. Through the optimization and comparison of algorithms, the accuracy is continuously improved

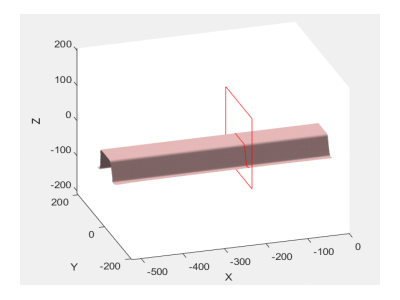

图例为电池包托盘,目标成型角度为90° 在部署智能系统后,误差减小 67.9%